Use the slider to compare the before and after photos

Dry-docking intervals are to be observed for class extensions.

At a Class Extension Survey the ship is to be inspected, if practicable, when it is not loaded, so that the hatches, the cargo holds, the tween-deck spaces, the watertight doors, etc. can be examined; if necessary, tanks will also be examined. In the case of oil tankers and ships carrying combined cargoes (e.g. OBO-ships) the ballast tanks located in the cargo area will be subjected to a general condition survey. An inspection of the machinery, including the electrical plant, is to be made to verify, in particular, satisfactory operation. Automatic/remote control systems are to be examined, taking into account records of operation.

2.4 Docking Surveys

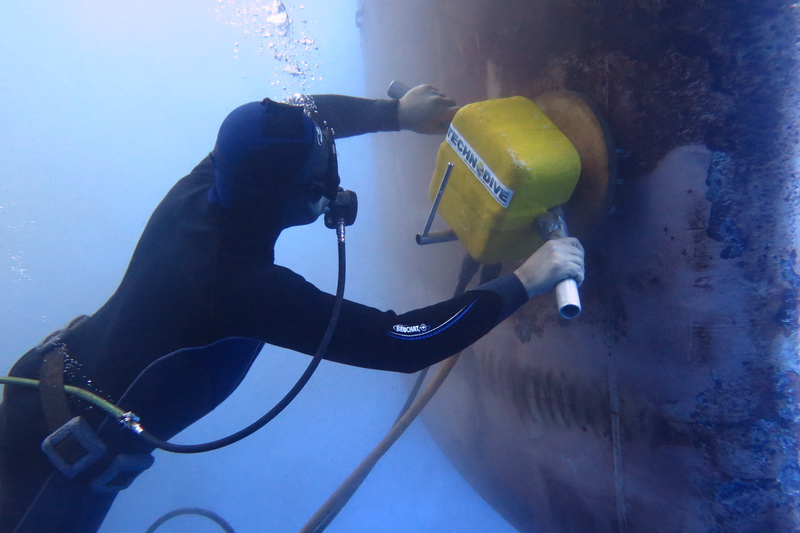

Underwater hull inspections at regular intervals shall ensure that the outside and the steering facility of a ship remain in a satisfactory condition. Such inspections are also carried out for the control of the propeller, the shaft-line bearings and seals. In addition inlet and outlet piping, valves, seachests and sea filters are examined.

A special type of underwater hull survey is the “in-water survey” which can be applied under special considerations.

For seagoing ships with character of class 100 A 4 an in-water survey may be recognized as a substitute for every second periodical bottom survey, provided

- the required special equipment is available, documents have been issued and trial requirements complied with and if the survey is carried out as required and with approved firms and satisfactory results,

- this survey is not part of a class renewal.

For ships of more than 10 years of age the intervals between dry-docking must not exceed 2.5 years.